The beer has dried up! Time to get back to business. Up first several IPAs. It’s time to brew a New England IPA (NEIPA). I have had a chance to try the great NEIPA Mass Riot from Prison City and a friend was nice enough to share some brews from Treehouse. The signature of this style is low bitterness but a huge juicy hop flavor and smell. It generally has a nice full/soft mouthfeel and is as cloudy as a glass of orange juice. Below are the keys to a good NEIPA from my research.

- Water profile – Opposite of traditional IPAs this style calls for high amounts of Chloride and low levels of Sulfate.

- Hops – Few if any hops added during the boil. Most of the hops should be added during a whirlpool. That whirlpool should occur at lower temp then right after knockout to protect the volatile hops oils you want in your beer. Citra, Mosaic, and Galaxy are very popular.

- Grain – Wheat, Oats, and Barley are popular to help add body and haze.

- Mash – Keep your mash pH around 5.3. Acidify your sparge water.

- Dry Hop – Should be done at full krausen not at the tail end of fermentation.

OG 1.065 / FG 1.013 / ABV 6.86% / IBU 36 / SRM 4.76

18# 2-row

4# Marris Otter

1# Flaked Oats

1# Flaked Barley

0.5# Wheat Malt

0.5# Honey Malt

1.5oz Warrior @ 60 min

2oz Citra @ 0 min

2oz Mosaic @ 0 min

2oz Simcoe @ 0 min

2oz Citra Whirlpool @ 160° for 30 min

2oz Mosaic Whirlpool @ 160° for 30 min

2oz Simcoe Whirlpool @ 160° for 30 min

3oz Citra Dry hop @ full krausen

2oz Mosaic Dry hop @ full krausen

1oz Simcoe Dry hop @ full krausen

3oz Citra Dry hop in keg

2oz Mosaic Dry hop in keg

1oz Simcoe Dry hop in keg

Water target – Ca 96 – Mg 12 – SO 74 – Na 11 – Cl 118

Mash at 153° for 60 minutes then raise to 168° and hold for 10 minutes. Collect 14 gallons and boil for 60 minutes. Produces 12 gallons at the end of the boil and 11 gallons in the fermenter.

GigaYeast – Vermont IPA Yeast

Brew day notes:

Salts – Added 6g of Gypsum and 14g of Calcium Chloride to 19 gallons

Mash was initially a pH of 5.56. Added 6ml of lactic acid to the mash and 5ml to the remaining sparge water. Mash pH settled at 5.35

I am going to add a splitter to also pump water inside the coil

Mashing

Mashing in TUN

Sweet wort run off

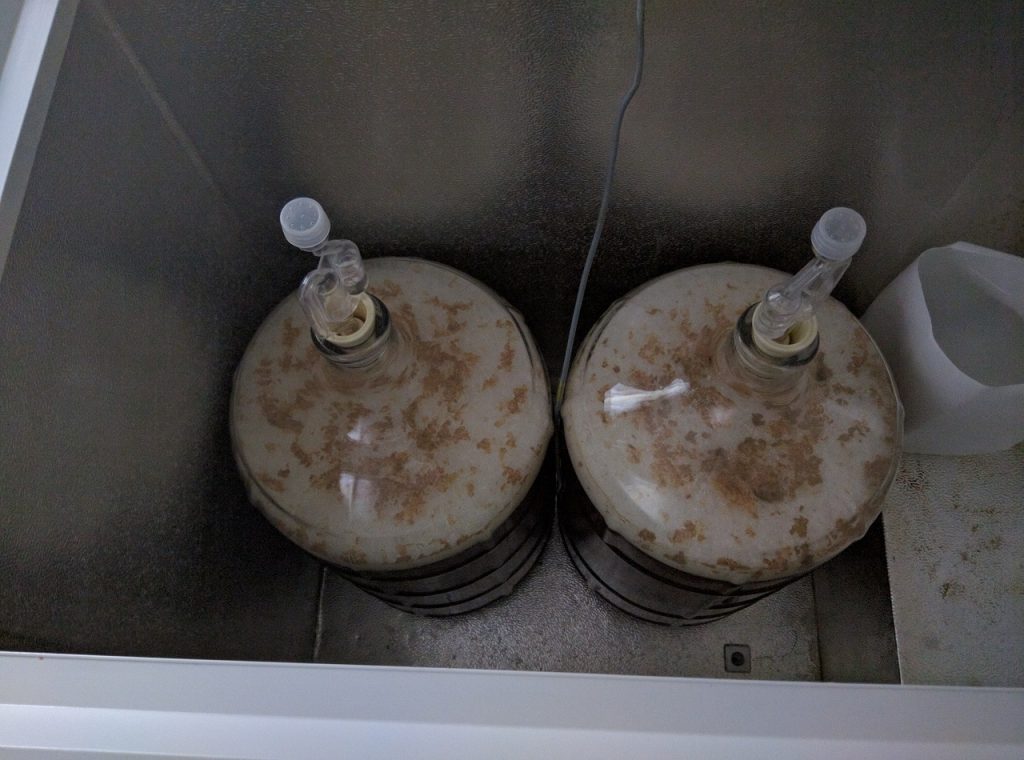

Hops explosion after dry hop at high krausen

Looking and tasting good on keg day (14 days after brew day)