I ordered one of Jaybird’s (norcalbrewingsolutions) great false bottoms. I will share pictures when it arrives. He was also running a great sale so I ordered the eight ball valves I will need. I went with the three piece design. Although I do not think they are necessary they allow for more flexible arraignment of the valve handle when using the 90 degree ELBarb bulkheads as dip tubes for the hot liquor tank and boil kettle.

NorCalBrewingSolutions.com

1x 18″ 20 gallon Spike Brewing kettle false bottom with handle

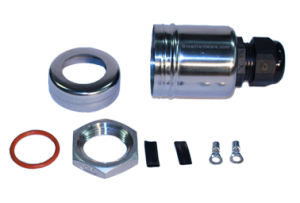

8x Three piece SS 1/2″ ball valve