It has been a struggling to find time to brew. Thankfully my Wife encouraged me to brew a week ago. So on short notice I pulled together a IPA recipe that uses a light malt base and some hops that I have on hand. If it’s good I make make it a few times to play with different hop combos.

Results: OG 1.057 (12 gallon) / FG 1.007 / ABV 6.56%

OG 1.058 / FG 1.010 / ABV 6.26% / IBU 57 / SRM 3.9

21# 2-row

2.5# Vienna

1oz Commet @ 60min boil

1oz Commet @ 15min boil

2oz El Dorado @ 15min boil

2oz Commet @ 2min boil

4oz El Dorado @ 2min boil

1oz Commet Dry Hop @ 5 days

5oz El Dorado Dry Hop @ 5 days

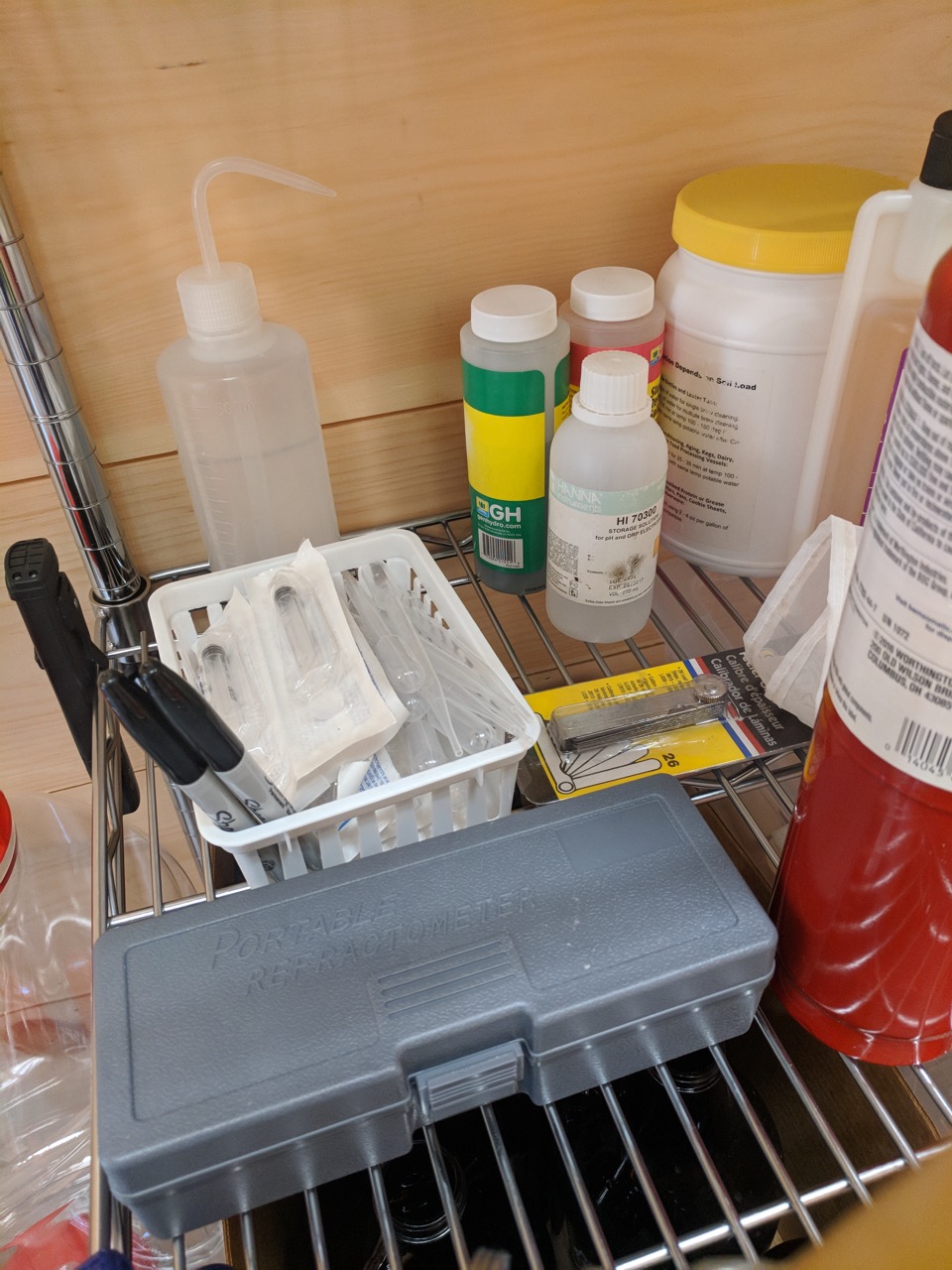

Water target – SO4 200 (25g Gypsum added to 19gal)

Mash at 152° for 60 minutes then raise to 168° and hold for 10 minutes. Collect 14 gallons and boil for 60 minutes. Produces 12 gallons at the end of the boil and 11 gallons in the fermenter.

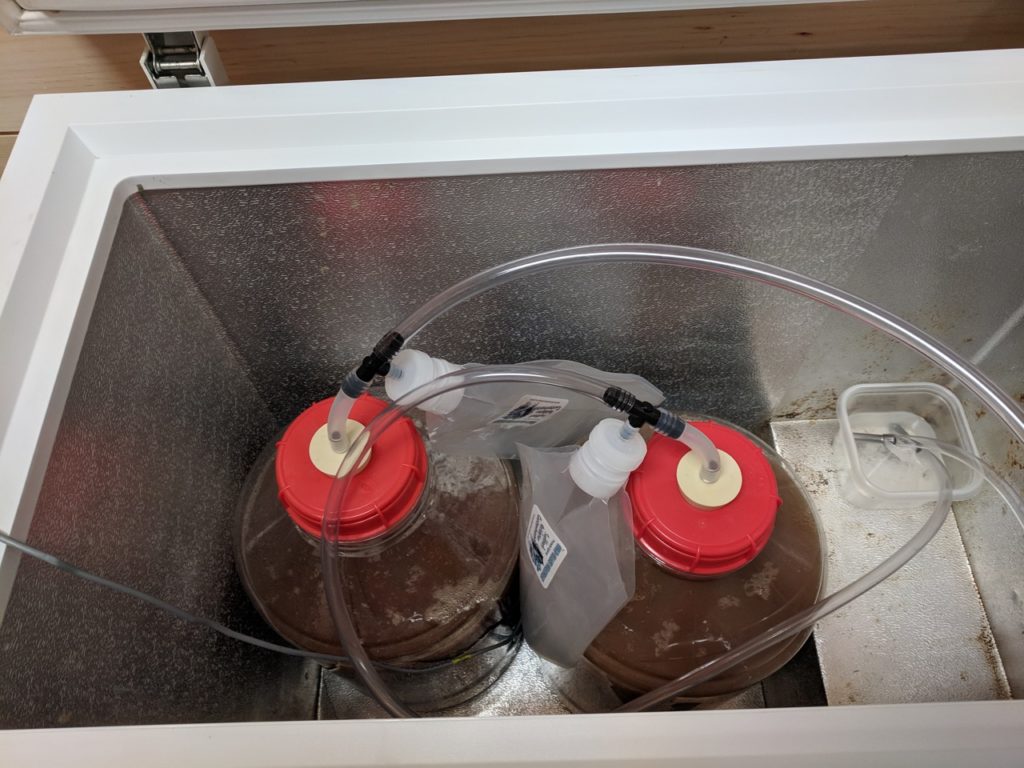

Fermentis – Safale – American Ale Yeast US-05

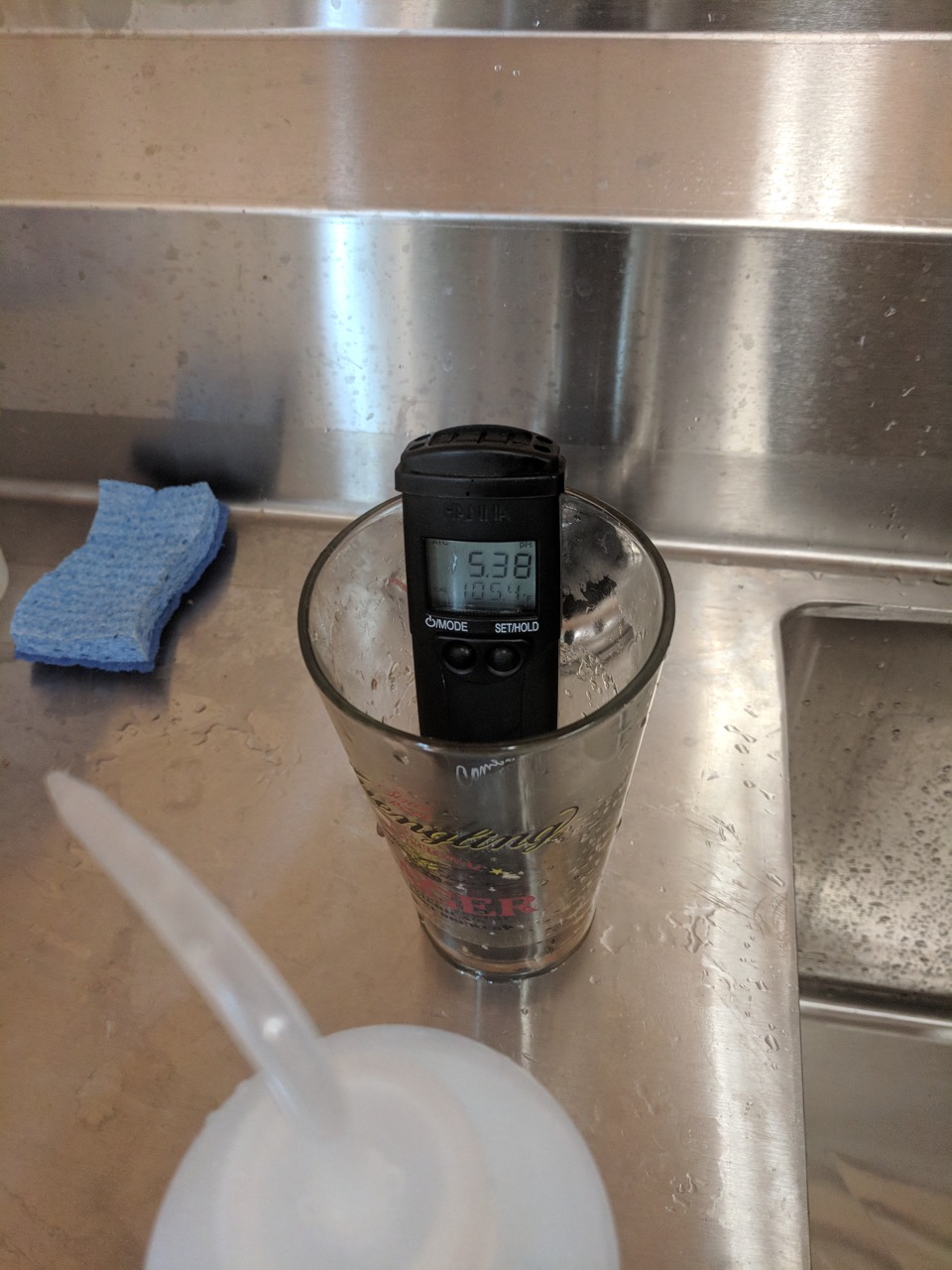

Start of Mash

End of mash

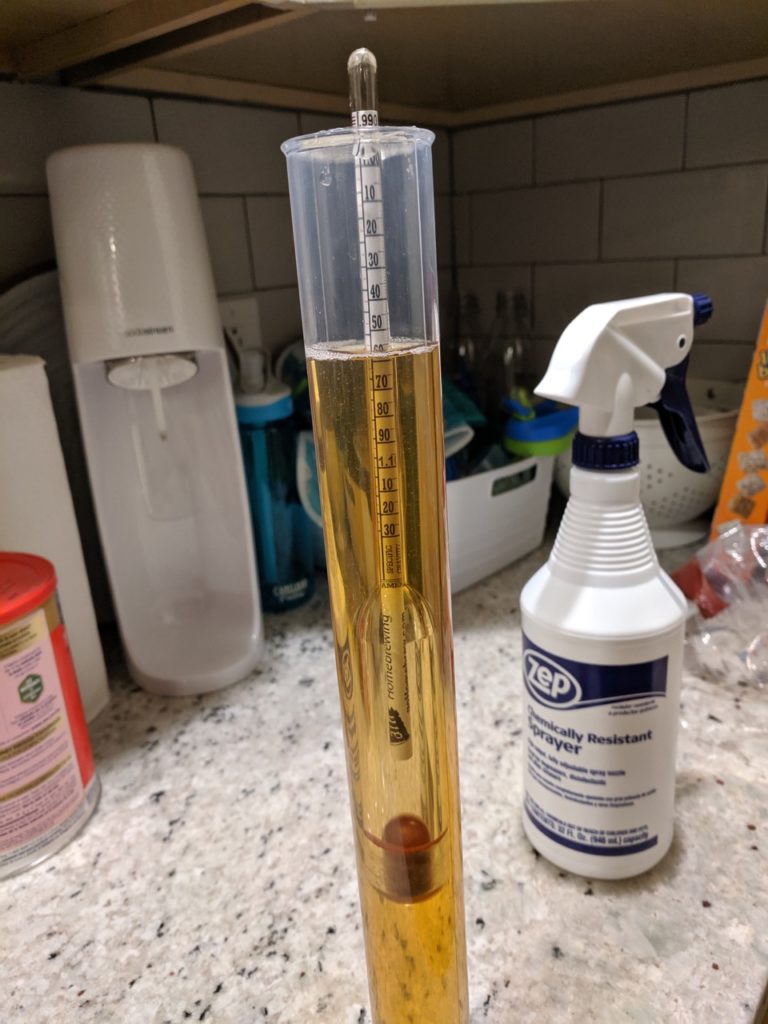

1.057 OG

Hop dam works decent and very easy to clean