I was able to acquire a used greenlee 1-1/4″ chassis punch for a good price on ebay. This is the largest and most expensive punch used for the the heating elements. The 13/16″ chassis and 1/2″ conduit punch were purchased new from all-spec.com. I also back decided to go back to sight glasses so I don’t have to remove the lids to check volumes. You could use a step bit to make these holes but due to the quantity I need to create I think it is worth the investment. I will likely sell them after I am done using them.

ebay.com

1x 1-1/4″ 730BB Chassis/Radio Punch (Heating elements)

all-spec.com

1x 13/16″ 730BB Chassis/Radio Punch (1/2″ Plumbing)

1x 1/2″ Conduit Slugbuster (Pannel buttons & switches)

brewhardware.com

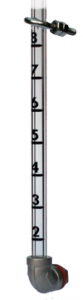

3x 20″ Weldless sight glass kit for pots

3x Additional numbers 16-25 gallon + 1/2 gallon marks

1x Tube cutter

1x Sight glass cleaning brush