A fellow member of my local homebrew club received a 53 gallon bourbon barrel as a birthday present. Several members are brewing the same stout recipe to fill the barrel. I will be adding 10 gallons to the total. Below is the recipe. I am currently waiting on an order of oat malt before I brew.

15# Marris Otter

6# Oat Malt

1.5# VIctory Malt

1.5# Chocolate Malt

1.5# Crystal 120

1.5# Carafa II

1# Roasted Barley (300 SRM)

3oz Magnum @ 60min

1oz Williamette @ 10min

Mashed at 136° and 156°

English Ale S-04

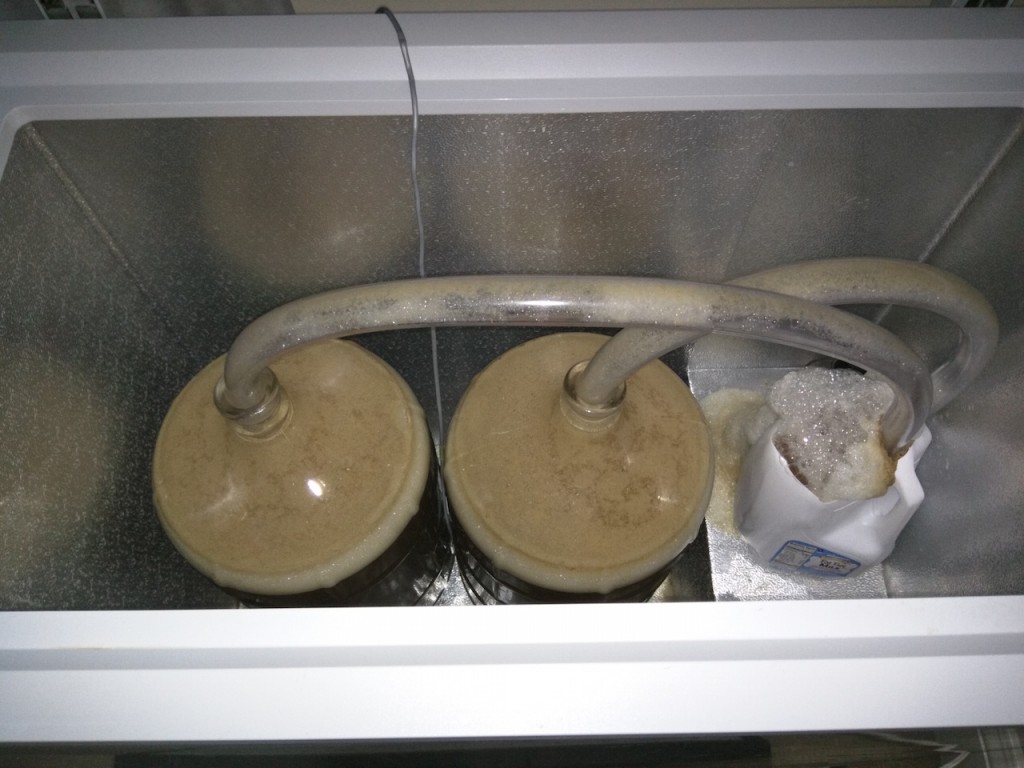

I ended up with a OG of 1.069. The beer needed blow off tubes less than 12 hours later and is now fermenting very aggressively. I need to figure out a better container for the blow off tubes since the container is now overflowing with krausen.