I stared a post called new projects in June 2015, all it had was three additions I wanted to make to the brewery. I promptly forgot about it until today while looking through draft posts. Funny enough the three items are three of my more resent adds to the brewery.

- Heating for fermentation

- A beer gun for bottling

- A pressurized racking system

I do heat my new brewing space but unless I am working in the space it is only in the 40s or 50s mid-winter. This means I need to heat my fermentation chamber. I am using the same FermWrap I use in the Keezer. This will also be useful for trying the new Norwegian Kveik yeast strains. These like to ferment hot and are very interesting and very different then the yeast I am used to. Check out Larsblog for info.

I finally splurged for a Blickman beer gun. I normally gravitate to DIY options and there are certainly lots of options to build a home made beer gun or counter pressure filler. In this case Blickman’s solution is very slick and what I can build with generic parts would not be as nice by a wide margin. For the price and savings of mine time researching/building/troubleshooting etc its a bargain.

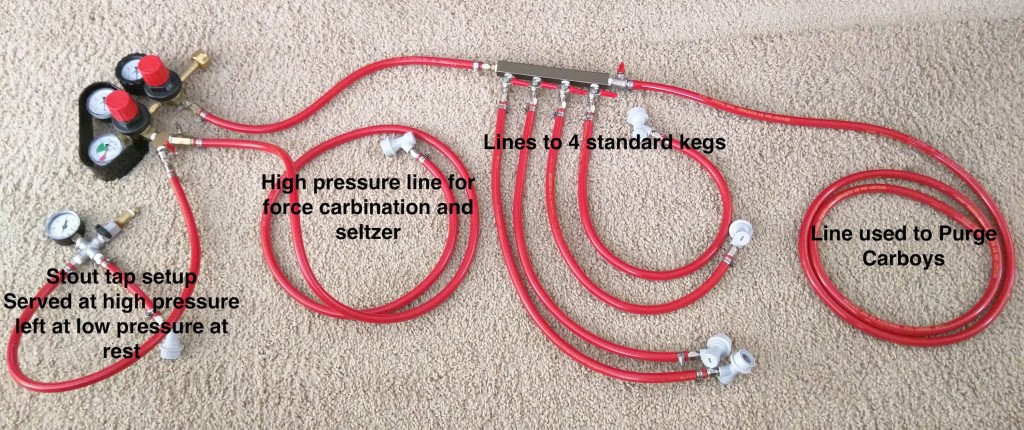

The last item is focused on limiting oxygen exposure during transferring to kegs. This is detailed in a separate post.